Top Hat Liners

Why Bother?

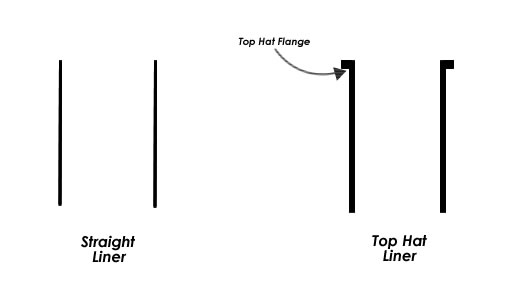

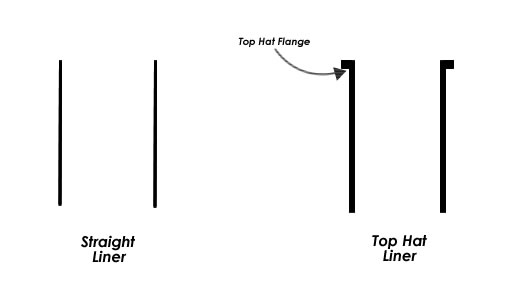

The Rover V8 engine has seen many variations since it's conception / modification from the Buick 215 of years gone by. The later adaptations of the engine, particularly the 4.6 litre, has been seen to suffer from leakage (in and out) of the cylinder walls. Sometimes refered to as 'Porosity' in the block, this results in pressurisation of the water system, water loss, overheating, hydraulic lock and eventually complete engine demise. The installation of top hat liners eliminates this issue. The flange at the top of the cylinder, and it's mating face that is machined into the block, is compressed between the head and the block and seals the cylinder completely.

Progress

There are further advantages to the addition of the flanged liner. The new liners are substantially thicker than the originals and we can therefore use them to create oversize bores and greater capacity engines. We have already developed a 96.5mm variant and may move further in the future.

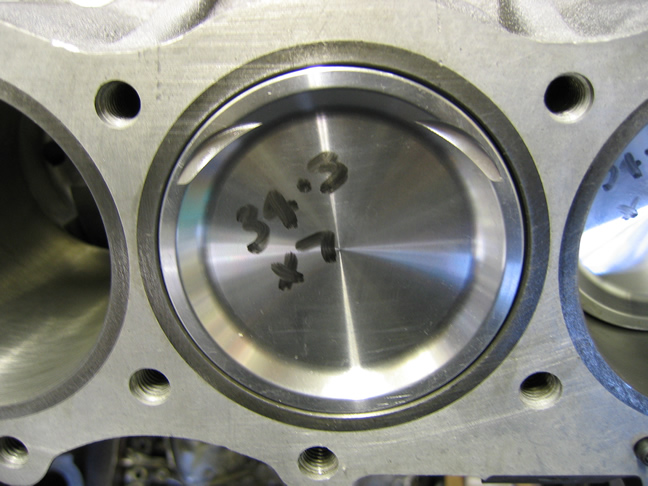

These Top hat liners, shown above left, have been fitted in order to repair an engine that had formed a cylinder / liner leak. At the same time the capacity has been 'upgraded' and the pistons replaced by 96mm Forged pistons. This a fairly common method of repair / upgrade for engines that have suffered a liner issue but also a very common first build for engines that we supply. An increasingly high percentage of the engines we build utilise the top hat liner. The engine on the right shows a standard liner in a late type block (notice the missing row of head bolt holes).

Advantages

The advantages of the top hat liner are clear. The 'porosity' problems that some Rover V8 Blocks have suffered in the past are eliminated completely. The liners can offer a bore of up to 96.5 (or theoretically 97mm) and so offer greater capacity engines without the need for very long stroke, this reduces piston speeds and makes an engine which revs more freely and has a higher rev limit, therefore giving more scope for power output.

We only use seasoned blocks when fitting top hat liners. The reasoning behind this is simple, a new engine has not had time to suffer the stresses and strains that will be caused when the engine is used and therefore can never be guaranteed to be fault free. If we use a seasoned block then we have a starting point which we can be fairly sure will not alter over time and therefore provide a stable and 'safe' engine.

We take great care to check the suitability of any cylinder block we use and 'Line Hone' the main bearing galleries to ensure staightness. We also fit new camshaft bearings and often have the block 'cross bolted' with a 4 bolt main cap to add rigidity to the 'bottom end'. Cylinder bores are then honed to size and finished to the highest standards with a cross hatch.

The cost of fitting top hat liners to your block - £1,605

(there is a surcharge of £350 if you do not supply a block)