Setting Follower Pre-Load

This is a commonly misunderstood procedure and is very important for correct engine performance and for the longevity of your camshaft.

Incorrect pre-load can result in poor performance, camshaft damage, excessive engine noise and damage to other drive train components. In short

Get It Right!

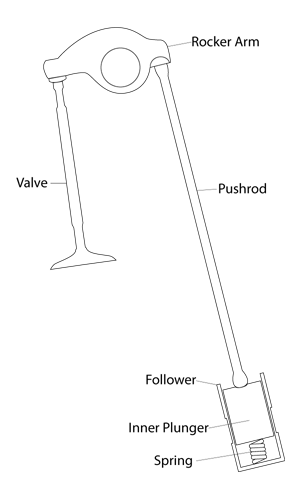

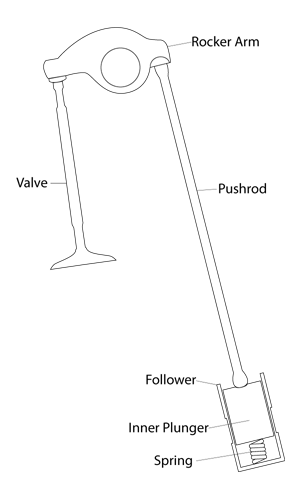

The hydraulic camshaft valve train shown above, is a fairly simple system for opening and closing the valves of the Rover V8 engine.

The system relies on oil pressure within the follower gallery to 'pump up' the centre of the follower and push the 'Inner Plunger' up against the pushrod.

There is a spring at the bottom of the follower as a final 'backup' should the system loose oil pressure. In setting the pre-load we are ensuring that the spring is

under slight compression with no oil in the system, and therefore ensuring that the camshaft, pushrod, rocker arm and valve are in constant contact.

In order to achieve this pre-load, we are looking for a depression of the 'inner plunger' by between 0.040" and 0.060" (40 to 60 thou or 1 to 1.5 mm). This actually

quite difficult to measure because of the limited space in the top of the follower. It can be done with a suitable right angled device with a known thickness, but even this is quite tricky to get right.

So we have a more reliable method for setting this up. There are several different combinations of pushrod and rocker arm that can be fitted to a Rover V8 valvetrain,

but this method will work for most of them.

If we fit a 'shim' beneath the rocker shaft pedestals, lifting the pivot point of the rocker arm upwards, there will be a relative movement of the end of the pushrod equal (within the tolerances we are

happy to accept) of 1.6 x the movement of the pedestal. This is because the rocker arm has a 1.6:1 length ratio. So for this example we will use a 0.032" (32 thou)

shim to achieve just over 0.050" (50 thou) movement at the end of the pushrod.

If the rocker assemblies are already fitted, then remove the 4 bolts and fit a 0.032" shim under each pedestal, then re-fil the bolts and tighten.

If you are using standard fixed length pushrods, then the pushrod should be just touching (but not depressing) the centre of the follower.

If this is the case, then you do not need to make any adjustments, simply remove the shims and tighten everything back down. If, however, the pushrod is depressing the follower inner plunger,

then you will need to add another shim to each pedestal, we would recommend 0.016" to begin with, then re-check. Repeat this process until you manage to get the pushrod

just touching the inner plunger. Now simply remove the original 0.032" shims leaving any subsequently added ones behind and tighten everything back down.

If, when you fit the first 0.032" shims the pushrods are clear of the inner plunger and loose, then you have a slightly more difficult task. You need to add 'more' preload

to the follower, and this can only be achieved by either using a longer pushrod, or shortening the pedestals. We usually recommend fitting adjustable pushrods at this point so that you can set the

pre-load for each cylinder individually.

If you have adjustable pushrods, then fit the 0.032" shims, adjust the pushrods so they are just touching the inner plunger, lock off the pushrods, then remove the shims.

The preload is now set!